Need to offload railcars? MEI has the equipment you need to quickly move inventory from rail into storage. MEI offers railcar unloading equipment engineered to meet the specific requirements of agri-chemicals.

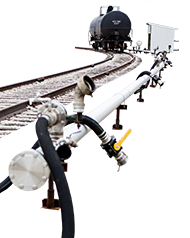

Railcar to Storage Unloading

This scalable system is designed to efficiently off-load 2-10 railcars into storage tanks. Each system comes with a single pump/plumbing station located centrally with multiple railcar hookups along a rail header.

Pump/Plumbing Station:

- 250-850 GPM straight centrifugal pump with 15-50 HP motor (depending on number of hookups)

- 4” basket strainer

- 2 - 4” butterfly valves to control flow along rail header to pump

- Air purge

- Stainless steel residual product collection tank

- 4” 304 stainless steel pipe with slip weld fitting

- 1-3” butterfly valve to control discharge flow

- Prefabricated 304 stainless steel components

Railcar Header:

- 6” 304 stainless steel schedule 10 pipe

- 2-10 Railcar hookups spaced 55’ apart

Railcar Hookup (Per Hookup):

- 25’ x 4” EPDM Suction/Discharge Hose

- 5” x 4” Aluminum railcar fitting

- Butterfly valve

- Sample port

Options: Place pump at rail header end instead of middle, 4” Railcar hookup hose instead of 3” (per hookup), 6" or 8" HDPE SDR11 pipe instead of 6” 304 stainless steel pipe